Shoulder Ballast Cleaner

As the global railway network advances toward higher speeds, greater capacity, and more intelligent maintenance, the stability of the track foundation remains the cornerstone of all operational objectives. As a global leader with decades of expertise in railway engineering machinery, AGICO Rail is committed to providing the most robust assurance for this foundation. Our integrated cutting-edge ballast cleaning solutions—combining R&D, manufacturing, and service—are designed to fulfill the mission of "Revitalizing Track Life." This product series is not only highly efficient engineering machinery but also a systematic tool for ensuring the long-term health, safety, and cost-effectiveness of railway arteries.

Send Enquire Now

Send Enquire Now

AGICO Rail Track Ballast Cleaning Machine

Railway ballast, the crushed stone layer beneath the sleepers, is the core cushioning and drainage layer of the track structure. Under constant stress, it can deteriorate—losing elasticity and drainage function—which leads to difficulties in maintaining track geometry, accelerated wear, and increased safety risks and maintenance costs.

The AGICO Rail full series of ballast cleaning machines is the ultimate solution developed to address this fundamental issue. Our machines execute a precise and efficient physical regeneration process: excavating contaminated ballast, thoroughly separating reusable stone from debris via an innovative screening system, and accurately refilling clean ballast. This process restores the ballast bed's key properties in a single operation, elevating track quality to nearly new-line standards and extending overhaul cycles multiple times. We offer not merely individual equipment but comprehensive ballast management value across the entire workflow.

Contact us for product catalog

Contact us for product catalog

Available Model of AGICO Ballast Cleaner

The primary shoulder maintenance model currently recommended by AGICO Rail is the ZYSZ-5 type. This model integrates our core engineering expertise, with its design entirely centered on the three principles of "precision," "efficiency," and "reliability."

ZYSZ-5 Shoulder Ballast Cleaner

Get Price Now

Get Price Now

Core Positioning: Specifically designed for cleaning contaminated ballast and refilling cleaned ballast in the shoulder areas of railway track beds.

Key Performance Parameters:

- Working Efficiency: Up to 500-600 cubic meters per hour, capable of quickly addressing long-distance shoulder contamination.

- Cleaning Width: Effectively cleans the shoulder area within a specific range outside the rail (exact width is adjustable based on conditions).

- Operating Mode: Utilizes side-oriented, angled excavation and lifting technology. As the machine moves along the track, its working unit extends towards the ballast shoulder to excavate the contaminated material.

Core Working Systems:

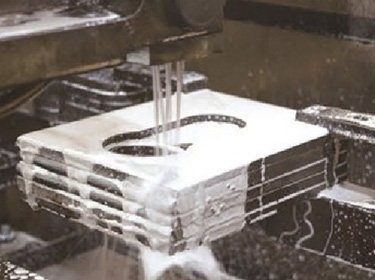

- Excavation and Conveying System: Equipped with high-strength, wear-resistant digging chains and scrapers to excavate dirty ballast from the shoulder and transport it upward via enclosed conveyor belts.

- Vibrating Screening System: The dirty ballast is delivered to a multi-stage vibrating screen. The screen meshes efficiently separate cleaned ballast meeting size specifications from soil, small particles, and waste.

- Ballast Return and Waste Handling System: The cleaned ballast is precisely returned to the excavated shoulder area to form the designed profile. The separated waste soil is conveyed to a following material collection car or a designated disposal area.

- Propulsion and Power: Features self-propulsion capability suitable for railway line environments. Powered by a high-power diesel engine providing reliable energy, with a hydraulic system driving all working units.

Technical Specifications:

| Parameter Item | Parameter Value |

|---|---|

| Gasoline Engine Model | GX270 |

| Engine Power | 5.1 KW |

| Engine Speed | 3600 r/min |

| Operating Efficiency | ≥2 km/h |

| Output Voltage | 12 V |

| System Pressure | 8 MPa |

| Fuel Consumption | 1.1 L/km |

| Unit Weight | 98 kg |

| Total Machine Weight | ≤464 kg |

| Dimensions (L×W×H) | 2800×2800×1200 mm |

Rail Track Cleaner Advantages

Choosing the AGICO ZYSZ-5 railway ballast cleaner means opting for a "surgical" maintenance solution focused on solving a specific problem. Its advantages are evident in:

1. Targeted Maintenance Capability

Unlike full-section cleaners, the ZYSZ-5 is specifically designed for shoulders. Its working unit can precisely locate and clean the critical drainage zone from the sleeper ends to the ballast toe, avoiding unnecessary disturbance to the sub-sleeper foundation and achieving precise "clean-where-needed" operation.

2. Superior Operational Economy and Flexibility

Efficient Independent Operation: This ZYSZ-5 railway ballast cleaner can independently complete shoulder cleaning tasks without supporting other large machinery. It is particularly suitable as core equipment for routine line maintenance and preventive upkeep, or as a supplementary profiling tool following major repairs.

Maximized Resource Utilization: Through efficient screening, the majority of usable, cleaned ballast is recovered on-site and returned, significantly reducing the need for new ballast supplement and the cost of waste transportation and disposal.

Modularity and Adaptability: The compact design allows some versions to be rapidly connected as functional modules to engineering vehicle chassis, enhancing operational flexibility and deployment speed.

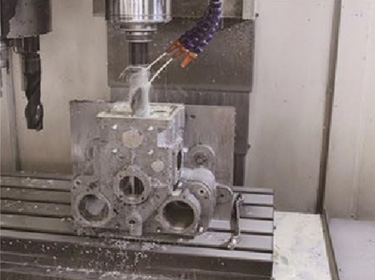

3. Reliable and Durable Engineering Quality

Reinforced Critical Components: Key wear-prone parts in the excavation and screening process use special wear-resistant steel and hardening treatments, significantly extending the service life of wear parts and reducing long-term operational costs for spares.

Stable System Performance: Optimized hydraulic and power matching design ensures stable performance output during continuous operation, resulting in low failure rates and high machine availability.

4. Improved Working Environment and Construction Safety

The ZYSZ-5 railway ballast cleaner machine operates along the trackline, with its working range concentrated on the shoulder, causing minimal interference to the main track structure. This allows greater flexibility in scheduling maintenance "possession windows" and can sometimes enable cautious operation even under adjacent line traffic conditions (subject to safety regulations), improving maintenance window utilization.

Application Areas

The AGICO shoulder ballast cleaner is the ideal choice for the following scenarios:

- Preventive Maintenance: Regularly cleaning track bed shoulders to prevent systemic drainage function decline caused by contaminant accumulation, addressing issues proactively.

- Specialized Defect Remediation: Targeted treatment for sections already exhibiting defects like pumping or hardened shoulders to restore drainage.

- Ancillary Operations for Major Repairs: Following full-section cleaning or track renewal projects, using this machine for fine grading and cleaning of shoulders to achieve comprehensive improvement in ballast bed quality.

- Maintenance in Specific Environments: Especially suitable for focused shoulder maintenance on dedicated freight lines (with severe coal/ore spillage), areas with high wind-blown sand, or sections with inherently poor subgrade drainage.

Why Choose AGICO Rail?

In the field of specialized equipment, AGICO Rail is your trustworthy partner:

Deep Focus, Professional Excellence: We are not just equipment suppliers. In the niche area of shoulder cleaning, we continue R&D investment. The ZYSZ-5 embodies our deep understanding of ballast bed drainage mechanisms and shoulder failure modes, exemplifying "using the right tool for the job."

Value-Driven Solutions: We provide not just a machine, but an economical and effective shoulder maintenance methodology. We are committed to helping our clients achieve the best line maintenance outcomes at the lowest total lifecycle cost.

Global Service and Technical Support: Leveraging AGICO's global service network, we provide timely spare parts supply, operator training, and on-site technical support to every client, ensuring equipment remains in optimal condition and delivers continuous value.

Reliable Quality Commitment: From material selection to manufacturing processes, we adhere to high-standard quality control systems. Every ZYSZ-5 cleaner leaving our factory undergoes rigorous testing to ensure its reliability and durability in harsh field environments.

Choosing the AGICO Rail ZYSZ-5 Shoulder Ballast Cleaner means choosing a precise, economical, and reliable method to safeguard the "healthy shoulders" of your railway track bed, fortifying the primary drainage defense line for line safety and stability.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!