Rail Gap Adjuster

AGICO Hydraulic Rail Gap Adjuster

The AGICO Hydraulic Rail Gap Adjuster is a precision device specifically designed for railway track maintenance. It is used to accurately adjust rail joint gaps caused by temperature fluctuations, mechanical stress, or construction factors. As one of the popular maintenance machines under AGICO Rail, it utilizes hydraulic power to provide controlled adjustment of track gaps, gauge, and expansion joints, ensuring smooth and safe train operation.

This equipment is primarily used for the local adjustment of gaps on jointed tracks. It precisely controls the gap size hydraulically, keeping it within permissible limits. Unlike a rail tensor used for stress relief in continuously welded rails (CWR), the gap adjuster does not alter the overall stress state of the rail. Timely and precise gap adjustment effectively reduces the risk of derailment, minimizes wheel-rail impact, significantly extends the service life of track components, and lowers long-term maintenance costs.

AGICO offers both unidirectional and bidirectional models, suitable for various rails from 50 to 75 kg/m. The unidirectional type features a simple structure, offering cost-effectiveness and reliable performance. The bidirectional type provides both push and pull functions, significantly improving efficiency, especially in confined spaces. As a manufacturer with over 20 years of experience, we are committed to providing efficient, reliable equipment solutions and cost-effective services for all types of railway maintenance organizations.

Available Models of AGICO Rail Gap Adjuster

To meet the requirements of different rail types, construction scenarios, and force specifications, AGICO offers a range of mature and reliable Rail Gap Adjuster models, forming a complete product matrix suitable for maintenance from light rails to heavy-haul freight lines.

| Model | YTF-250 | YTF-400 | YTF-400 II (Bidirectional) |

|---|---|---|---|

| Drive Type | Hydraulic | Hydraulic | Hydraulic |

| Max. Adjustment Force | 250 kN | 400 kN | 400 kN (Push/Pull) |

| Working Stroke | 140 mm | 140 mm | 140 mm |

| Core Function | Unidirectional Push | Unidirectional Push | Bidirectional Push & Pull |

| Suitable Rail Profile | 30-43 kg/m | 43-75 kg/m | 43-75 kg/m |

| Total Weight | ~55 kg | ~80 kg | ~133 kg |

| Key Advantage | Lightweight, Portable, Cost-Effective | Powerful Thrust, Wide Applicability | Dual-Function, No Repositioning Needed, Multiplies Efficiency |

YTF-250 Hydraulic Rail Gap Adjuster

The most lightweight model in the series, weighing only about 55 kg, facilitating easy on-site transport and rapid deployment. Particularly suitable for daily maintenance and gap adjustment tasks on 30 kg/m to 43 kg/m rails, offering both economy and practicality.

Get Price Now

YTF-400 Hydraulic Rail Gap Adjuster

A well-balanced mainstay model delivering a powerful thrust of up to 400 kN, easily handling mainstream heavy rails from 50 kg/m to 75 kg/m. In a single operation, it can push 4-5 pieces of 12.5-meter-long 60 kg/m rails.

Get Price Now

YTF-400 II Hydraulic Rail Gap Adjuster (Bidirectional)

The technology-integrated flagship model. Its most revolutionary feature is the integrated hydraulic reversing valve, allowing seamless switching between push and pull functions via a handle. This is a significant advantage in confined spaces like tunnels, bridges, or turnout areas, enabling bidirectional adjustment without repeatedly repositioning the equipment. This increases construction efficiency by up to 3 times compared to unidirectional models. It is also equipped with features like a digital pressure gauge and displacement sensor for full-process precision control.

Get Price NowAdvantages of Rail Gap Adjusters

Choosing an AGICO Rail Gap Adjuster means opting for a smarter, safer, and more reliable maintenance method.

Millimeter-Level Precision Control

Utilizing precise hydraulic cylinders with measurable strokes and clear scale indicators, the rail gap adjustment accuracy can be strictly controlled within ±1 mm. This eliminates human adjustment errors at the root, reducing potential risks caused by improper gaps by over 60%.

Exceptional Operational Efficiency

Traditional manual adjustment requires multiple workers and is time-consuming. Using AGICO equipment, a single adjustment operation can be shortened to 3-8 minutes, improving overall efficiency by 5-8 times. This significantly reduces line possession time, creating greater value for operations.

Robust Environmental Adaptability & Safety

- Wide Temperature Range Operation: Core components are specially treated to operate stably in extreme ambient temperatures from -30°C to +60°C.

- Comprehensive Safety Protection: All models feature a four-level safety mechanism and an overload protection system. When the system pressure reaches the preset 52 MPa safety threshold, the relief valve opens automatically, effectively preventing equipment overload damage or plastic deformation of the rail.

- Ergonomic Design: Features a foldable handle designed for ergonomics, with an operating force of less than 450N. The non-slip rubber base and magnetic fixing devices ensure stable positioning of the equipment on the rails, guaranteeing safe operation.

Rugged Durability & Easy Maintenance

The main structure uses high-strength alloy steel, with key moving parts treated for wear resistance and rust-proof coating. Unidirectional models boast a simple structure with an extremely low failure rate; bidirectional models are reasonably designed for easy maintenance, ensuring long service life and high availability even in harsh maintenance environments. Contact us for product catalog

Contact us for product catalog

Applications

The AGICO Rail Gap Adjuster is a powerful assistant in various railway maintenance scenarios:

- Standardized Rail Gap Adjustment: Periodic adjustment of rail joint gaps according to seasonal temperature changes to prevent track buckling in summer or joint pull-apart in winter.

- Pre-Welding Operations: Precisely moving rail ends before flash-butt welding or thermite welding to reserve the perfect gap and achieve accurate alignment.

- Turnout & Special Section Maintenance: Used to adjust the longitudinal position of components like switch rails and frog points, eliminating impact and noise caused by improper displacement. Especially suitable for areas with strict geometric requirements like bridges and tunnels.

- Emergency Incident Handling: Can quickly push together or pull apart broken rail gaps in case of rail breakage, creating conditions for subsequent emergency repairs.

- Track Overhaul & Renovation: Controlled shifting and fine-tuning of rail segments during long rail laying, stress release, or track realignment projects.

Why Choose AGICO?

We understand that choosing equipment means choosing a long-term partner. AGICO's value extends beyond the product itself, embodied in a comprehensive support system:

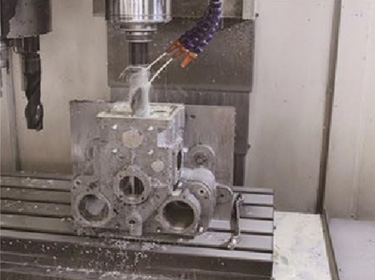

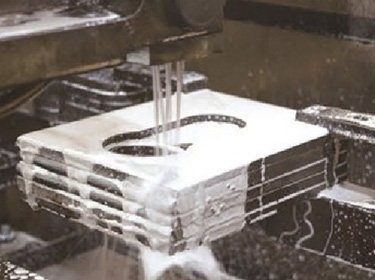

- Professional Manufacturing & Quality Assurance: We operate a modern production base spanning over 12,000 square meters, equipped with a full-process setup from CNC machining centers and heat treatment workshops to complete assembly and testing lines. Strict adherence to the ISO9001 Quality Management System ensures every unit leaving the factory undergoes precision assembly and rigorous testing, guaranteeing reliable performance and readiness for immediate use.

- Strong R&D & Technical Capability: AGICO boasts an R&D team comprised of over ten senior engineers. We not only provide standard products but also offer personalized custom design solutions and supporting construction advice based on your specific rail profile, on-site space constraints, or unique operational conditions.

- Comprehensive Full-Cycle Service: From pre-sales technical connection and site condition surveys to free technical training and on-site commissioning guidance upon equipment delivery, AGICO stands by your side. We are committed to providing timely original spare parts support and professional technical consultation, safeguarding the stable operation of your equipment throughout its entire lifecycle.

- One-Stop Solution Provider: Beyond the Rail Gap Adjuster, AGICO's product line includes various other railway maintenance machinery and tools such as rail grinders, drilling machines, tamping machines, rail tensors, track jacks, and more. Choosing us means gaining access to coordinated, highly compatible, one-stop equipment solutions.

The unimpeded flow of the railway network begins with the precise control of every millimeter. AGICO is willing to leverage our over twenty years of professional expertise and innovative technology to provide you with the most robust support for track maintenance. Please feel free to contact us anytime to obtain detailed product information, customized solutions, or quotations. Let's work together to safeguard the safety and efficiency of railway transportation.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!