Rail Tamping Machine

Send Enquire Now

Send Enquire Now

The AGICO Rail Tamping Machine is an indispensable, precision core piece of equipment in modern railway track construction and maintenance operations. Under the combined effects of long-term high-speed train operation, natural environmental changes, and natural ballast settlement, railway tracks inevitably develop geometric deviations—such as irregularities in longitudinal level, alignment, and cross-level. These deviations not only affect the smoothness of train operation and passenger comfort but also pose significant safety hazards. The core mission of AGICO's Tamping Machine is to efficiently restore the track's design smoothness and geometric parameters through automated, high-precision operation.

Our railroad tamping machine utilizes advanced hydraulic vibration and squeezing technology, simulating and surpassing the principles of manual tamping. During operation, pairs of tamping tines accurately insert into the ballast on both sides of the sleeper. High-frequency vibration fluidizes the ballast stones, followed by the application of immense inward squeezing force to rearrange and densely compact the ballast beneath and around the sleeper. This process firmly lifts and stabilizes the rail and sleeper, providing a solid, uniform support foundation for the steel artery. Whether for the final profiling of new lines or the periodic maintenance and overhaul of existing tracks, the AGICO Tamping Machine is a key technological asset for ensuring line quality, extending maintenance cycles, and enhancing operational safety.

AGICO Railroad Ballast Tamper Models

| Parameter / Model | YD-22 Hydraulic Diesel | YD-22II Hydraulic (Petrol) | YD-22III Smart Hydraulic Unit | ND-4.2×4 Flexible Shaft | YCD-32 Switch/Turnout | DG-550×4 Electric Unit |

|---|---|---|---|---|---|---|

| Drive Mode | Diesel (SF190) | Petrol | Diesel or Petrol | Internal Combustion | Diesel or Petrol | Electric (Generator) |

| Rated Power | 7 kW | 9.5 kW | 9.5 kW |

9.5kW (Single) 4.0kW×2 (Dual) |

7.0 kW | 550W × 4 (Motor) |

| Tamping Efficiency | ≥ 270 sleepers/hour | > 260 groups/hour | ≥ 270 sleepers/hour | 240–320 sleepers/hour | Not specified | Not specified |

| Tamping Depth | 110 ± 10 mm | 110mm ± 10mm | 110 ± 10 mm | Not specified | Not specified | Not specified |

| Exciting Force | 22 kN | 22kN | 22 kN | Not specified | Not specified | Tamping Force: 2.8kN |

| Machine Weight | 439 kg | 1385 kg (Frame) | 1385 kg | Not specified | 418 kg | 26.5 kg / pick |

| Core Features | Water-cooled diesel, double-guide-column frame, good stability | Dual-cylinder lifting, optimized hydraulics, auto rail clamp | Remote-controlled, electronic system, high intelligence | Single engine drives four picks, flexible shaft, portable | Designed for turnouts/frogs, hydraulic movement | Generator-powered, four independent picks, eco-friendly |

| Primary Application | Concrete & steel sleeper lines | Post-maintenance tamping, standard gauge | New lines & major overhauls | Standard lines & turnouts | Turnouts, frogs, guard rails | Emission-sensitive areas, powered sites |

YD-22 Hydraulic Diesel Tamping Machine

YD-22 Hydraulic Diesel Tamping Machine.jpg) YD-22II Hydraulic Rail Tamping Machine (Petrol)

YD-22II Hydraulic Rail Tamping Machine (Petrol) ND-4.2×4 Flexible Shaft Rail Tamping Machine

ND-4.2×4 Flexible Shaft Rail Tamping Machine DG-550×4 Electric Rail Tamping Machine Unit

DG-550×4 Electric Rail Tamping Machine Unit YCD-32 Hydraulic Rail Switch / Turnout Tamping Machine

YCD-32 Hydraulic Rail Switch / Turnout Tamping MachineYD-22 Hydraulic Diesel Tamping Machine

This is an efficient and reliable basic hydraulic tamping model. It uses a water-cooled diesel engine for robust power. Its double-guide-column frame and single-cylinder lifting structure ensure stability during tamping, with tines penetrating 110mm beneath the sleeper for compaction. Equipped with a swing-type walking frame for easy lateral movement on the track, it is suitable for routine tamping on various concrete and steel sleeper lines.

YD-22II Hydraulic Rail Tamping Machine (Petrol)

As the petrol-powered version of the YD-22, it features optimized upgrades in structure. It employs a double-guide-column frame with a dual-cylinder lifting system for more stable vertical motion of the tamping unit under continuous vibration. The hydraulic system uses crimped hose fittings with an enlarged diameter, reducing oil flow resistance and improving efficiency. Its automatic rail clamping function simplifies operation, making it a high-performance tamper for standard gauge lines.

YD-22III Smart Hydraulic Rail Tamping Machine Unit

This is the third-generation intelligent model of the YD-22 series, representing the advanced level of AGICO tampers. Its key feature is the remote-controlled travel frame and electronic control system (including electric start and remote functions), enabling automatic travel and remote operation, significantly boosting work efficiency and safety. While retaining the reliable tamping mechanism of its predecessors, it adds safety features like night work lights and protective mesh guards. Available with diesel or petrol engine options, it flexibly handles demanding maintenance and new line construction tasks.

ND-4.2×4 Flexible Shaft Rail Tamping Machine

This model features a unique flexible shaft drive design. A single engine simultaneously drives four tamping picks, enabling dual-operator协同 work, achieving an efficiency of 240-320 sleepers per hour on one rail. The entire machine is lightweight with traveling wheels for quick on/off track movement and relocation. With a low failure rate and easy maintenance, it is an ideal choice for maintenance teams seeking high cost-effectiveness and high mobility.

YCD-32 Hydraulic Rail Switch / Turnout Tamping Machine

This is specialized equipment designed to solve the difficult tamping problem in turnout areas. Turnouts have complex structures where standard tampers struggle to operate. The YCD-32 can move flexibly left and right within the turnout area, effectively tamping key sections like switch points, frogs, and guard rails. Its lightweight structure and simple operation make it essential machinery for ensuring track stability in turnout zones.

DG-550×4 Electric Rail Tamping Machine Unit

This is an electric tamping solution powered by a generator set. One generator set supplies power to four independent electric tamping picks, each weighing only 26.5 kg for easy carrying. The entire unit can move freely on the track, featuring a compact and adaptable structure. It produces zero on-site emissions and low noise, making it particularly suitable for environmentally sensitive areas like tunnels and urban settings, or locations with power access.

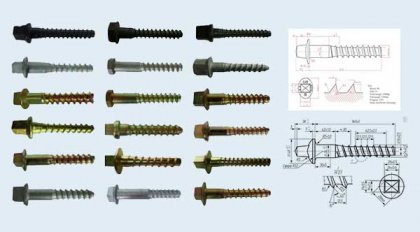

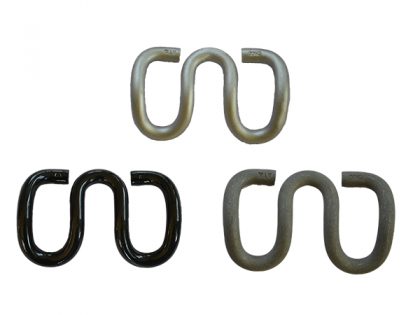

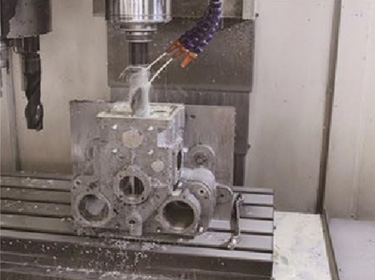

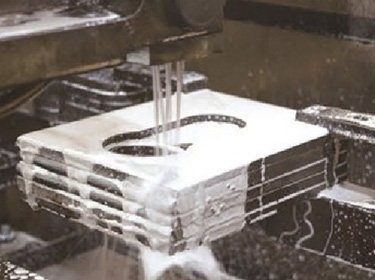

AGICO Rail Tamping Machine Details

AGICO Rail Tamping Machine Details

Selection Guide Summary

You can quickly filter based on your core task:

- Efficient Tamping for Regular Lines: For stability and reliability, choose the YD-22 Diesel; for automated features, choose the YD-22III Smart unit.

- Specialized turnout tamping: The dedicated model YCD-32 is essential.

- High Mobility & Cost-Effectiveness: Choose the ND-4.2×4 Flexible Shaft Tamping Machine, ideal for rapid redeployment and dual-operator work.

- Environmentally Sensitive Areas / Powered Environments: Choose the DG-550×4 Electric Tamping Unit.

Advantages of AGICO Ballast Tamping Machine

Contact us for product catalog

Contact us for product catalogOur rail tamping machine combines efficiency, durability, and intelligent design to deliver long-term value. Below are its key advantages, presented concisely:

High Efficiency & Cost Reduction

Operating at 280–600 sleepers per hour, our machine far surpasses manual work. It requires only 1–2 operators, reduces track closure time, and lowers both labor and maintenance costs through intelligent control.

Uniform Compaction & Long-Term Stability

Precise hydraulic and electronic control ensures even tamping depth and vibration. The high-frequency system delivers dense, uniform ballast compaction, extending track life and minimizing frequent maintenance.

Broad Adaptability

Compatible with 43 kg, 50 kg, and 60 kg rails without complex adjustments. Suitable for tunnels, bridges, mountains, and urban rail. Available in gasoline, electric, and hydraulic power options.

User-Friendly Operation & Maintenance

Ergonomic design with anti-vibration handles reduces fatigue. Modular structure allows easy part replacement, and intuitive controls enable quick training for non-specialists.

Energy Saving & Eco-Friendly

Low noise and low emissions make it suitable for urban and sensitive environments. Energy-saving vibration modules reduce fuel and power consumption.

Durable & Economical

Core components use premium brands (e.g., Honda engines, SKF bearings) for reliability. Designed for over 5 years of service with long maintenance intervals and genuine spare parts at competitive costs.

Customizable & Compatible Solutions

Full range of models (hydraulic, electric, internal combustion, flexible-shaft) for various scenarios. Customizable for special gauges, narrow spaces, or power needs, and compatible with existing maintenance systems.

Proven Technology & Full Support

Industry-leading tamping force and frequency. Integrated measurement system corrects track geometry in real time. We provide training, after-sales, parts, and remote support, with experience in meeting international standards.

Application of Rail Tamper

- New Railway Construction: Final compaction of the ballast bed and fine adjustment of track geometry after track and ballast laying to meet operational standards.

- Track Overhaul and Intermediate Repair: Restorative compaction of the ballast bed following the work of ballast cleaning or rail renewal machines, rebuilding the track foundation.

- Routine Preventive Maintenance: Periodic fine-tuning and correction of track geometry to prevent minor deviations from developing into major faults.

- Specialized Fault Remediation: Targeted intensive tamping for subgrade settlement zones, mud-pumping areas, and curved sections with heavy rail wear.

- Maintenance in Complex Areas: Track upkeep in high-speed turnout zones, hub stations, marshalling yards, at bridge ends, and inside tunnels.

- Industrial and Port Sidings: Reinforcement and maintenance of tracks subjected to heavy loads and frequent impact loads.

Why Choose AGICO?

- Profound Industry Expertise: Decades of R&D experience; we understand the processes and challenges.

- A "One-Stop" Solution Provider: We provide machines, consultation, planning, training, and upgrades.

- Global Service and Support Network: Multiple service centers and warehouses for rapid response and genuine spare parts worldwide.

- Continuous Innovation and R&D Investment: We apply latest technologies to keep clients at the technological forefront.

- Customer Success-Oriented Partnership: We are involved throughout the process to maximize your return on investment.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!