Rail Bolt Wrench Machine

AGICO Railroad Bolt Wrench Machine

Send Enquire Now

Send Enquire Now

As the lifeline of modern transportation, the safety and stable operation of railways are directly linked to the national economy and the safety of people's lives and property. Within the complex track system, tens of thousands of bolts play the critical role of connecting rails, fastening clips, and securing sleepers. With over twenty years of deep cultivation in the rail maintenance equipment sector, the AGICO Group has developed a full range of Railroad Bolt Machines (also known as rail impact wrenches, hydraulic bolt wrenches), leveraging our profound understanding of industry needs and continuous technological innovation. We are committed to providing efficient, reliable, and intelligent bolt fastening solutions for global railway construction and maintenance.

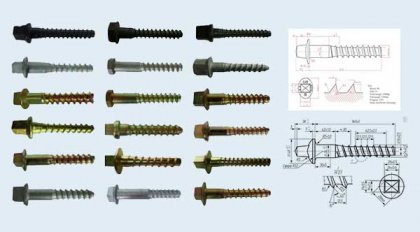

The AGICO railroad bolt machine is a mechanized tool specifically designed for the installation, tightening, and loosening of railway track bolts. It has revolutionized the traditional labor-intensive model, addressing three core pain points in track maintenance: low efficiency, inconsistent torque, and high labor intensity. Our product line covers multiple power forms including internal combustion engine drive, electric, hydraulic, and battery-powered options, perfectly adapting to all-scenario operating environments—from plateau tunnels to urban subways, and from new line construction to daily inspection and repair. Every piece of equipment is designed and manufactured in strict compliance with international and industry standards such as TB/T, CE, and CRCC, ensuring that safety and quality are never compromised in the pursuit of efficiency.

Available Models of AGICO Rai Bolt Wrench

AGICO offers a diverse product series to meet the needs of different working conditions, budgets, and efficiency requirements. Below is an introduction to our core products:

1. Internal Combustion Impact Wrench Series (Portable, Efficient, Field-Ready)

This series uses gasoline or diesel engines for power, requires no external power source, and is especially suitable for continuous, high-intensity work in field, remote, or power-scarce environments.

- NLB-1900 Portable Impact Wrench: Weighs only about 20 kg, portable by a single person. Equipped with a high-power two-stroke engine, it delivers a maximum torque of up to 1900 N·m, easily handling high-strength bolts of M30 specification and above. Its compact design and excellent balance make it the ideal choice for maintenance in confined or complex areas like tunnels, turnouts, and bridges.

- NLB-500 Portable Impact Wrench: Even lighter and more agile, with a net weight of 18 kg. Torque output is no less than 500 N·m. Suitable for vertical or horizontal operation on sleeper bolts and fishplate bolts, commonly used in emergency repairs.

- NLB-300 I/II Bolt Machine: Features a unique four-wheel travel device, allowing free movement switching between tracks and ground, significantly reducing handling frequency and labor intensity. With a maximum rotation torque of ≥300 N·m, it is a classic model for replacing heavy manual labor.

NLB-1900 Portable Impact WrenchGet Price Now

NLB-1900 Portable Impact WrenchGet Price Now NLB-500 Portable Impact WrenchGet Price Now

NLB-500 Portable Impact WrenchGet Price Now NLB-300 I/II Bolt MachineGet Price Now

NLB-300 I/II Bolt MachineGet Price Now2. Double-Head/Hydraulic Bolt Wrench Series (Batch Operations, Precise & Efficient)

Designed for the paired distribution of sleeper bolts, enabling simultaneous operation and doubling efficiency. Particularly suitable for new line laying or large-scale centralized maintenance.

- NLB-600 Double-Head Internal Combustion Bolt Machine: Equipped with dual sockets for simultaneous tightening or loosening of two bolts. Uses stepless speed change technology for precise torque adjustment. Instantaneous maximum loosening torque reaches 600 N·m, effectively handling rusted bolts and significantly improving work efficiency.

- YLB-700 Hydraulic Bolt Wrench: Utilizes fully hydraulic static torque output, operating smoothly without impact. Its core advantage lies in high-precision torque control, with setting accuracy up to ±1 N·m and a digital display. The torque range can be precisely adjusted between 80-350 N·m, with automatic unloading and alarm upon reaching the set value, fully meeting the stringent requirements for fastening quality on high-speed railways and passenger dedicated lines. The double-socket design allows for single-piece operation efficiency of less than 4 seconds.

NLB-600 Double-Head Bolt MachineGet Price Now

NLB-600 Double-Head Bolt MachineGet Price Now YLB-700 Hydraulic Bolt WrenchGet Price Now

YLB-700 Hydraulic Bolt WrenchGet Price Now3. Battery-Powered Wrench Series (Green, Flexible, Future-Oriented)

Keeping pace with new energy trends, offering quiet, zero-emission operation solutions suitable for urban areas and tunnels with noise and environmental requirements.

- LLB-2000 Battery Impact Wrench: Uses imported batteries and components with a durable aluminum alloy body. Maximum loosening torque reaches 2000 N·m, while weighing only 8.7 kg, combining great power with extreme portability and outstanding mobility.

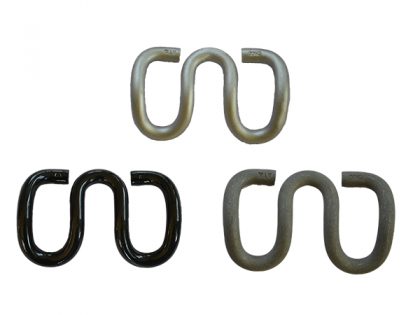

4. Specialized Tool Series

- JGB-Ⅲ Elastic Rail Clip Wrench: Specifically designed for disassembling and installing elastic rail clips. Dual-head operation provides a thrust of up to 20 KN, enabling clip disassembly/assembly in 4 seconds or less, making it a powerful tool for track replacement and overhaul projects.

LLB-2000 Battery Impact Wrench

LLB-2000 Battery Impact Wrench JGB-Ⅲ Elastic Rail Clip Wrench

JGB-Ⅲ Elastic Rail Clip WrenchAdvantages of Our Rail Impact Wrench

The AGICO Railroad Bolt Machine is not just a tool; it is an engineering solution that enhances the efficiency of the entire maintenance operation system. Our advantages are reflected in the following dimensions:

Ultimate Efficiency, Rebuilding Productivity

Whether it's the instantaneous impact torque of up to 1900 N·m for quickly loosening seized bolts, or the precise hydraulic fastening of 4 seconds per piece with dual heads, AGICO equipment can increase work efficiency to more than 6 times that of manual labor, significantly shortening track possession time and directly creating economic value.Precise Torque, Ensuring Line Safety

Torque is the lifeline of bolted connections. Our equipment provides multi-level precise control, from mechanical adjustment to digital presetting and display. Especially the hydraulic series, achieving "stop when tightened" precise control, fundamentally prevents bolt loosening due to insufficient torque or bolt damage and stress concentration caused by over-tightening, laying a solid foundation for the long-term stability of track geometry.Full-Scene Adaptation, Comprehensive Coverage

We offer four major power solutions: internal combustion, electric, hydraulic, and battery. Whether you face field lines without power, confined spaces in tunnels and turnouts, urban areas sensitive to noise, or high-speed rail projects with stringent precision requirements, AGICO always provides a matching solution, achieving true all-scenario, all-weather operational capability.Human-Centric Design, Reducing Labor Intensity

We have a deep understanding of maintenance workers' operational conditions. Products feature lightweight design (lightest model only 8.7kg), two-stage shock absorption handles, low center of gravity or upright operation structures, and integrated travel devices, maximizing operator stamina savings, liberating personnel from heavy physical labor, and enhancing operational safety.Robust and Durable, Easy Maintenance

Key components use high-strength alloys and internationally renowned brand engines (e.g., Honda, Briggs & Stratton). The housing protection rating reaches IP40, resistant to oil and corrosion. Modular design allows for quick replacement of wear parts like motors, reducers, and sockets, effectively reducing maintenance costs and downtime.Application

AGICO Railroad Bolt Machines are widely used in all stages of the railway lifecycle:

- New Line Construction & Track Laying: Large-scale fastening of sleeper bolts, fishplate bolts, and elastic clip fastener systems; key equipment for improving track laying speed and initial installation quality.

- Daily Maintenance & Periodic Inspection: Used by track gangs for periodic checking, adjustment, and re-tightening of bolt torque; essential machinery for preventive maintenance.

- Overhaul & Renewal Projects: Quick removal of old bolts and installation of new systems during major construction like rail replacement, sleeper renewal, and turnout replacement, ensuring project progress.

- Operations in Special Sections: Portable and specialized models are indispensable in complex areas where large maintenance machinery cannot access, such as bridges, tunnels, and station turnouts.

- Emergency Rescue & Repair: Can be rapidly deployed for repairs after natural disasters or accidents, restoring track connections and minimizing traffic disruption time.

Why Choose AGICO?

Choosing AGICO means choosing a trustworthy long-term partner, not just an equipment supplier.

Profound Industry Accumulation

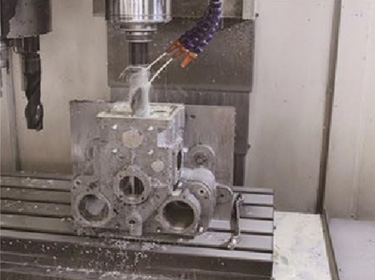

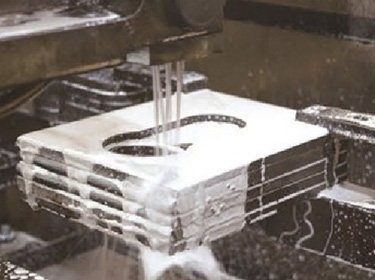

Over 20 years of focus and cultivation have given us a deep understanding of every detail of railway maintenance. Our products have been successfully exported to more than 40 countries and regions worldwide, including markets like Chile, Indonesia, Turkey, and Nigeria, receiving broad empirical recognition.Strong Manufacturing & R&D Capabilities

We operate a 30,000-square-meter heavy-duty production workshop equipped with advanced CNC machining centers. The company holds more than ten national invention patents. Continuous product iteration stems from our own R&D engine, ensuring technological leadership.Reliable Quality & Certification System

Product quality is AGICO's dignity. Key products have passed authoritative certifications such as CE and CRCC, complying with international railway industry standards, and can be directly applied to national railway, high-speed rail, and urban rail transit projects.Customer-Centric Full-Cycle Service

We provide end-to-end services from on-site operation training and safety guidance to annual torque calibration. A global spare parts network and a responsive technical support team aim to maximize your equipment availability and reduce total lifecycle operating costs.Customized Solution Capability

We support compatibility integration with customers' existing equipment systems and can provide customized development based on special operational needs, ensuring seamless integration of equipment into your workflow.

Safe and efficient tracks begin with a correctly fastened bolt. The AGICO Group invites global railway partners to join us. Let us use professional equipment and dedicated service to jointly safeguard the safety and smooth operation of every section of track, driving the world forward efficiently.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!