Rail Drilling Machine

Send Enquire Now AGICO Rail Drilling Machine is a critical professional equipment in railway construction and maintenance operations, specifically designed for efficient and precise drilling on rails. As an indispensable part of the rail joining process, this equipment is primarily used to drill bolt holes required for installing fishplates, ensuring secure connections between rail sections and guaranteeing the smoothness and operational safety of the railway line. It is widely used in various scenarios such as new line construction, existing line maintenance, turnout replacement, signal system installation, and emergency repairs, serving as core machinery for railway maintenance departments, engineering units, and equipment leasing companies to enhance work efficiency and ensure construction quality.

Send Enquire Now AGICO Rail Drilling Machine is a critical professional equipment in railway construction and maintenance operations, specifically designed for efficient and precise drilling on rails. As an indispensable part of the rail joining process, this equipment is primarily used to drill bolt holes required for installing fishplates, ensuring secure connections between rail sections and guaranteeing the smoothness and operational safety of the railway line. It is widely used in various scenarios such as new line construction, existing line maintenance, turnout replacement, signal system installation, and emergency repairs, serving as core machinery for railway maintenance departments, engineering units, and equipment leasing companies to enhance work efficiency and ensure construction quality.

This product incorporates advanced power systems and precision mechanical structures, delivering outstanding performance in drilling accuracy, operational efficiency, and environmental adaptability. Its design balances powerful performance with portability, featuring a compact structure, intuitive operation, and an effective cooling system that significantly extends tool life. To meet diverse on-site needs, AGICO offers a complete series of drive models, including internal combustion engines for remote power-less environments, quiet electric models, flexible and eco-friendly lithium battery versions, and manual models for special applications. This comprehensive range covers all types of working conditions from national railways and urban rail transit to industrial dedicated lines.

As an established professional manufacturer with years of industry experience, all AGICO's main models have obtained the rigorous China Railway Product Certification (CRCC), and their reliability has been long-term validated in the market. We provide not only high-performance complete machines but also complete drilling tool accessories and comprehensive technical service support.

AGICO rail drill details

AGICO rail drill details

AGICO Rail Drilling Machine Models

| Parameter / Model | NZG-31 Ultra-Light Internal Combustion | NLQ-45 Concrete Sleeper Bolt Drilling & Pulling | ZG-31 / LZG-33 Electric | NZMZ-20 Wooden Sleeper |

|---|---|---|---|---|

| Drive Mode | Internal Combustion (Honda GX35) | Not Specified | Electric Motor (Battery / Mains) | Internal Combustion |

| Power / Output | 1.0 kW | Not Specified | 1.0 kW / 220V | 1.42 kW |

| Drilling Diameter | Ø9.8 – Ø36 mm | Not Specified | Ø9.8 – Ø36 mm | Ø17.5 mm (Max) |

| Drilling Time | ≤ 30 seconds (Rail) | Not Specified | ≤ 40 seconds (Rail) | ≤ 20 seconds (Sleeper) |

| Machine Weight | 17 kg | Split design for easy mobility | 15.5 kg | 14 kg |

| Core Features | Lightest in its class, auto water supply, drill bit included | Dual-function: drilling & bolt extraction, non-damaging to concrete sleeper | Intelligent control, millimeter precision, auto water cooling | Designed for wooden sleepers, integrated cooling & dust suppression |

| Primary Application | Maintenance, overhaul & emergency repair on 43-75kg/m rails | Drilling & extracting bolts in concrete sleepers/integrated track beds | Maintenance & repair on all rail types below 75kg/m | Drilling holes in wooden sleepers for track laying & maintenance |

NLQ-45 Concrete Sleeper Bolt Drilling & Pulling Machine

NLQ-45 Concrete Sleeper Bolt Drilling & Pulling Machine NZG-31 Ultra-Light Internal Combustion Rail Drilling Machine

NZG-31 Ultra-Light Internal Combustion Rail Drilling Machine NZMZ-20 Wooden Sleeper Drilling Machine

NZMZ-20 Wooden Sleeper Drilling Machine ZG-31 / LZG-33 Electric Rail Drilling Machine

ZG-31 / LZG-33 Electric Rail Drilling MachineNZG-31 Ultra-Light Internal Combustion Rail Drilling Machine

This is AGICO's flagship lightweight rail drilling model. With a total weight of only 17 kg, claimed as the lightest domestically in its category, it offers exceptional portability for field carrying and on-track operation. Designed for standard 43-75kg/m rails, it features an auto-locking rail clamp ensuring drilling accuracy (tolerance ≤1mm). Its automatic water supply system reduces friction and cools the drill bit during operation, significantly boosting work efficiency and extending tool life. This model comes with a standard drill bit, offers strong versatility, and is an ideal choice for routine maintenance and emergency repairs by permanent way departments.

NLQ-45 Concrete Sleeper Bolt Drilling & Pulling Machine

This is a highly specialized machine with the core function of non-destructive drilling and extraction of bolts from concrete sleepers or integrated track beds. Its technology ensures no damage to the concrete body, allowing extracted bolts to be re-anchored into the original hole immediately, greatly reducing material waste and repair time. The machine uses a split design where the main unit and clamping device can be separated. It can be mounted on a mobile chassis or used manually with just the main unit, offering flexibility, easy movement, and quick deployment/removal from the track to minimize disruption to line operations.

ZG-31 / LZG-33 Electric Rail Drilling Machine

This is a high-precision, intelligent electric solution. It utilizes intelligent precision control technology for fast motor response and stable output, achieving millimeter-level drilling accuracy, paired with a self-locking rail clamp for secure positioning. It also features an automatic water cooling function to effectively extend drill bit life. The machine has a compact structure for good portability and is not limited by battery capacity, allowing for all-day continuous drilling. It is a reliable choice for electrified line sections or working conditions with requirements for low noise and emissions.

NZMZ-20 Wooden Sleeper Drilling Machine

As the name suggests, this machine is designed specifically for drilling holes in railway wooden sleepers. The body is compact and weighs only 14 kg, offering excellent portability. Powered by a 1.42kW engine, it delivers high drilling efficiency, completing a hole in approximately 20 seconds. The machine integrates a water supply system for cooling and dust suppression during drilling, which reduces tool wear and improves the on-site working environment. The handle integrates controls and an engine safety lock, featuring an ergonomic design that effectively reduces labor intensity.

Selection Guide

- General Rail Drilling Needs: For field environments without power, prioritizing ultimate portability, choose the NZG-31. For scenarios with power access or requiring continuous, quiet operation, choose the ZG-31/LZG-33.

- Concrete Sleeper Bolt Handling: For bolt replacement or repair work, the specialized machine NLQ-45 is essential.

- Wooden Sleeper Work: For drilling holes in wooden sleepers during track laying or maintenance, choose the dedicated model NZMZ-20.

All main AGICO models have obtained CRCC (China Railway Product Certification), and their reliability has been long-term validated in the market. If you can specify the particular application scenario (e.g., new line construction, existing line maintenance, or handling sleepers of a specific material), we can offer more targeted advice.

Advantages of Railroad Drill

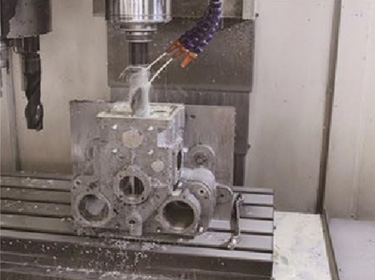

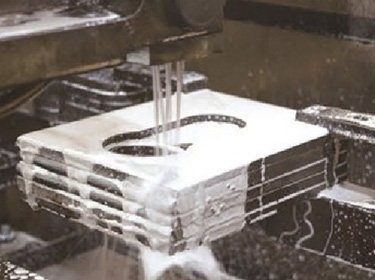

1. Superior Drilling Precision & Efficiency

Precision Positioning System: Equipped with fine-tuning calibration and clear scale indicators, ensuring bolt hole position accuracy within ±0.5mm, fully compliant with international rail standards such as UIC, BS, and AREA.

High-Efficiency Power Configuration: Utilizes high-power hydraulic motors or electric drives, delivering consistent high-torque output. Drills a standard hole in 50mm thick rail in just 45-60 seconds.

Intelligent Cooling Circulation: Integrated efficient water-cooling system effectively controls drilling temperature, extending drill bit life by over 30% while reducing metal dust.

2. Excellent Engineering & Durability

High-Strength Structure: Main body constructed from special alloy steel with heat-treated critical load-bearing components. Mean Time Between Failures (MTBF) exceeds 2000 hours.

Full Rail Profile Compatibility: Quick-adjust clamping system compatible with all standard rail sections from 30 kg/m to 75 kg/m, with changeover time under 2 minutes.

Environmental Adaptability: Sealed to IP54 rating, operates reliably in temperatures from -20°C to 50°C, suitable for rainy, dusty, and other harsh site conditions.

3. Ergonomic Operation & Safety Assurance

Easy Handling Design: Total weight only 65-85kg, featuring balanced handles and lifting points, allowing easy transport by two personnel.

Intuitive Control Interface: Ergonomically laid-out controls enable quick proficiency without extensive training.

Comprehensive Safety Protection: Three-point safety lock mechanism, fully enclosed guard, and overload protection system ensure safe and controlled operation.

Operational Procedure Guide

- Quick Installation & Positioning: Place the machine at the predetermined rail location. Adjust the universal clamp to a secure state. Use the positioning ruler to determine the hole center.

- Tool Preparation: Select and install the appropriate diameter drill bit onto the spindle. Connect the cooling hose and fill the tank.

- Drilling Execution: Start the machine, activate the cooling system, and steadily advance the feed handle while observing the drilling process.

- Completion & Cleanup: Retract the drill bit upon completion. Turn off power and cooling. Release the clamp and remove the machine.

Professional Maintenance Recommendations

- Daily Care: Clean the machine surface and drain the cooling tank after each use.

- Periodic Maintenance: Check hydraulic oil level and lubricate all moving parts every 200 operating hours.

- Long-Term Storage: Clean thoroughly, apply anti-rust oil, and store in a dry, ventilated environment.

Get a free quote

Get a free quote

Frequently Asked Questions (FAQs)

Q1: What types of rail is the AGICO drill suitable for?

A: Our drill features an adjustable clamping design, compatible with major global standard rails including Chinese standard rails (50kg/m, 60kg/m), European UIC rails, American AREA rails, and all other 30-75 kg/m profiles.

Q2: How does the equipment operate at remote sites without power?

A: We offer multiple power options, including diesel hydraulic power pack versions and generator power supply solutions, ensuring reliable operation in any field condition.

Q3: How is drilling accuracy guaranteed?

A: The machine is equipped with a precision positioning ruler and fine-adjustment device, combined with a rigid frame design, ensuring hole position accuracy within ±0.5mm and perpendicularity deviation within 1°, fully meeting track technical standards.

Q4: Is the equipment maintenance complicated?

A: AGICO drills feature a modular design. Daily maintenance involves simple cleaning and lubrication. We provide detailed bilingual maintenance manuals and video guides, enabling basic maintenance by regular technicians.

Q5: What is the delivery time after ordering?

A: Standard models are available from stock, with shipment within 7 working days after order confirmation. Special configuration models have a production lead time of 15-30 days. We provide global logistics services to ensure safe and timely delivery.

Why Choose AGICO?

Industry Experience & Certifications

AGICO has over 20 years of experience in railway equipment manufacturing. Our products are certified under the ISO9001 Quality Management System and carry CE safety marks, serving railway clients in more than 50 countries and regions worldwide.

Full Lifecycle Service Support

We provide a one-stop service solution from technical consultation and equipment selection to operator training and after-sales support. A 24/7 technical support hotline ensures your issues are promptly addressed.

Customization Capability

We can provide customized solutions based on your specific requirements, including special hole diameter needs, dedicated clamp designs, and specific power configurations.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!