Buy high quality railroad tie plates from professional manufacturer - AGICO

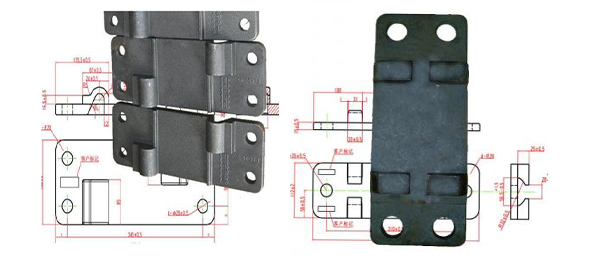

From outward appearance, the railroad tie plate is a thick steel panel that sits between the rails and rail sleepers on a standard railway. Look closer, you will find railroad tie plate is generally tapered at either end, it was shaped like this to improve stability and reduce torsion and twisting along the rails. According to statistics, rails installed with tie plates are better able to maintain their position, because the structure helps to standardize the width, or gauge, of the track along its length. Considering these factors, rail workers use railroad tie plates to extend the longevity of the railroad, and to maximize safety of passengers and rail workers.

Functions of railroad tie plates

Each railroad tie plate features either a single or double-shoulder construction. On a double-shoulder unit, the tapered ends of the plate are raised to create a sunken bed in the middle, which must be sized to match the width of the rail. The rail fits snugly between the two shoulders, which increases support and stability on either side of the rail. Single-shoulder railroad tie plates contain only one raised edge, which fits against one side of the rail. These versatile units allow workers to use the same tie plates on rails of any size.

Railroad tie plates help to evenly distribute the weight of the train and cargo over a larger portion of each tie. This reduces friction between the rails and ties, and helps the wooden ties last longer than they otherwise would. It also helps the metal rails wear more evenly, and allows them to maintain a smoother, more uniform surface. Because each railroad tie plate adds an extra step to the construction process, railroads with tie plates take longer to build, and often come with higher labor and material costs. Tracks constructed without wooden ties generally don't require railroad tie plates.

Railroad tie plates help to evenly distribute the weight of the train and cargo over a larger portion of each tie. This reduces friction between the rails and ties, and helps the wooden ties last longer than they otherwise would. It also helps the metal rails wear more evenly, and allows them to maintain a smoother, more uniform surface. Because each railroad tie plate adds an extra step to the construction process, railroads with tie plates take longer to build, and often come with higher labor and material costs. Tracks constructed without wooden ties generally don't require railroad tie plates.

Advantages of railroad tie plates

- Railroad tie plates distribute the load from the rail to the ties and provide uniform bearing surface for the rail and prevent rail movement.

- Railroad tie plates provide proper cant and obtain central loading and more uniform wear on the rail head.

- Railroad tie plates hold the rail rigidly to gauge and protect ties against undue wear, which prolongs the service life.

- Railroad tie plates are fabricated from heavy hot-rolled steel sections which are punched and sheared to size.

Some notes on the design of railroad tie plates

On the process of tie plate production, railroad tie plates should be accepted on the basis of actual weight as applied to the entire order, except that any weight supplied in excess of 3% over the weight calculated from the specified dimensions shall be the responsibility of the manufacturer.

- Spike holes are typically punched from the bottom of the tie plates.

- Measurement for size and location should be determined from the punch entering surface.

- Measurement of the hole location should match to the spike holes to each other.

- Measurement of the skewness of spike holes should be in relationship to the designed location of the rail base for line holes and to the sheared edge for hold down holes.

Limits on spike holes punching of railroad tie plates

Holes are not punched closer than 1-5/8 inches center to center in a rail tie plate.

Outer edge of any hole is not closer than 1/2 inch to the rolled edge for plates up to 3/8 inch in end thickness; or closer than 5/8 inch to the rolled edge for plates greater than 3/8 inch up to 1/2 inch in end thickness.

Outer edge of any hole is not closer than 1 inch to the sheared edge of the tie plate.

Outer edge of any hole is not closer than 1/2 inch to the rolled edge for plates up to 3/8 inch in end thickness; or closer than 5/8 inch to the rolled edge for plates greater than 3/8 inch up to 1/2 inch in end thickness.

Outer edge of any hole is not closer than 1 inch to the sheared edge of the tie plate.

Why choose AGICO railroad tie plates

We offer various sizes of new double shoulder railroad tie plates for 5 1/2” and 6” base rail (including the exclusive supply of a Plan 4, 7 3/4” x 11” plate for 5 1/2” base rail) and a large supply of various relay single and double shoulder tie plates. The 11” railroad tie plates and relay plates will offer you appreciable savings and economies, especially for industrial sidings and in-plant track. In ordering, identify rail weight and section, such as 115 lb. AREMA, and/or width of rail base, and size of spikes. As a professional manufacture of all types of railroad fasteners, AGICO can offer immediate shipments of railroad tie plates in any quantities from nationwide warehouses to all over the world.

Get In touch Now!

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!